Think Warehousing is Simple? Here’s Everything You Didn’t Know

Table of Contents

As everybody knows, warehousing involves more than just keeping goods in storage; it involves handling them wisely, quickly, and properly. Warehouse management may be a game-changer in this situation.

What is warehouse management exactly, then? In short, it is the process of organizing and improving every activity that takes place within a warehouse, from receiving shipments and keeping track of inventory to choosing and sending out reserves. It's the unseen force behind a smooth supply chain, making sure the correct product gets to the right location at the right time.

Imagine managing a warehouse now that is free of miscounts, delays, and lost goods. That is the strength of well-run warehouses. They save expenses, improve accuracy, raise customer happiness, and maintain the synchronization of your whole logistics network. Efficiency is a competitive advantage rather than merely a goal.

However, warehouse managers haven't always been as smart. Clipboards and manual ledgers have given way to barcode scanners, cloud-based software, and now automation driven by artificial intelligence. It takes minutes now instead of hours. By combining robots, real-time analytics, and the Internet of Things, smart warehousing removes uncertainty and puts complete control at your fingertips.

Understanding warehouse management is now necessary, regardless of whether you're running a modest storage facility or a multi-location business. The first step to a system that truly functions is this tutorial.

Ready to Elevate Your Business? Unlock the Power of Logistics Software Today to Maximize Efficiency, Slash Costs, and Stay Ahead of the Competition!

Core Components of a Warehouse Management System (WMS)

In contemporary warehousing, a warehouse management system (WMS) serves as the digital foundation. What makes it work is as follows:

- Inventory Tracking & Visibility

Learn about stock placements, movements, and levels in real time throughout the whole warehouse. - Receiving & Put-Away Workflows

Make incoming logistics more efficient by automating product inspections, labeling, and the best possible storage locations. - Picking, Packing & Order Fulfillment

Using intelligent picking pathways, packing instructions, and accuracy-focused procedures may accelerate fulfillment. - Shipping & Delivery Coordination

Utilize dispatch tracking, carrier integration, and automatic label creation to streamline outbound operations. - Returns & Reverse Logistics Management

Easily handle returns and make sure that each item is tracked down, replenished, or processed quickly. - Real-Time Data Access & Reporting

Use live dashboards and comprehensive reports to measure KPIs, keep an eye on performance, and make better decisions.

Types of Warehouse Management Systems

It's important to select the appropriate kind of Warehouse Management System Software Development; there is no one-size-fits-all solution. Various arrangements accommodate varying operational complexity, finances, and company demands. The most common kinds are briefly summed out here:

- Standalone WMS

A system developed especially to run warehouses. It's ideal for businesses who want a particular solution without including more broad corporate technology. While having a lot of warehouse functionality, it could not connect well with other departments like accounting or procurement. - Cloud-Based WMS

Cloud-based solutions are adaptable, flexible, and sometimes less expensive initially. They are hosted online and may be accessed from any place. They are perfect for businesses who have many locations or are growing. Your IT load is lessened since the provider frequently takes care of upgrades, backups, and support. - Integrated WMS with ERP/SCM

A larger platform for supply chain management (SCM) or enterprise resource planning (ERP) includes several systems. The gain? unified data, optimized processes, and a single source of truth for all departments, including customer support, logistics, and finance and human resources. - Open Source WMS: Pros and Cons

Open source appeals to tech-savvy teams because it offers customization and flexibility without requiring license costs. But it often requires more internal resources to deploy, manage, and secure. It's perfect for businesses who want control and have the internal expertise to handle it.

Each type of WMS offers benefits, and your company's size, complexity, and technological expertise will determine which is ideal for you. Choosing the right one requires more than just features; it also requires that it align with your long-term operational strategy.

Technologies Transforming Warehouse Management

Not only is contemporary warehouse management evolving, but it is also being totally revolutionized by cutting-edge technology that boosts efficiency, clarity, and speed beyond anything before observed. Technology is transforming the warehouse floor into a hub for creativity in the following ways:

- Warehouse Automation (AGVs, Conveyor Systems)

Intelligent conveyor systems and Automated Guided Vehicles (AGVs) drastically reduce fulfillment time, simplify material flow, and eliminate manual work. - Internet of Things (IoT) in Warehouse Monitoring

Real-time information on inventory, temperature, humidity, and equipment performance is provided by smart sensors and networked devices, enabling preventative choices and safer surroundings. - Artificial Intelligence for Demand Forecasting

AI helps you improve inventory levels and cut waste by predicting future demand by analyzing historical data, market trends, and consumer behavior. - Voice and Vision Picking Systems

Voice commands and augmented vision tools are examples of hands-free technology that helps employees do jobs precisely, reducing mistakes and increasing efficiency. - Robotics and Drones in Modern Warehousing

While drones save hours of human labor by doing stock checks and inventory audits at large facilities, robots help with repetitive chores like selecting and sorting. - Mobile & Wearable Devices for Staff Efficiency

Staff members are kept informed and linked via tablets, smart scanners, and wearable technology like AR glasses or smartwatches, which enhances work completion and real-time communication. - Augmented and Virtual Reality in Warehouse Training

Without interfering with business operations, AR and VR produce immersive training environments that shorten onboarding times, increase safety, and get employees ready for real-world situations.

These technologies are tools, not just trends, that broaden the scope of what is possible in warehouse management. To accept them means to stay ahead, not to catch up.

WMS Integrations and Ecosystem Fit

Despite being strong on its own, a warehouse management system's (WMS) real power is found in how successfully it fits with your larger company environment. Your whole supply chain infrastructure is connected, communicated with, and collaborated with via a WMS.

A good WMS must be able to interact with other business systems, such as CRM (Customer Relationship Management), ERP (Enterprise Resource Planning), TMS (Transportation Management System), and OMS (Order Management System). Better departmental collaboration is made possible by these linkages, which guarantee a smooth data flow and do away with silos.

You get real-time visibility into purchasing, financial reporting, and inventory expenses, for example, when your WMS communicates directly with your ERP. Processing orders becomes more accurate and faster when it is in sync with your OMS.

APIs and middleware platforms are crucial to these connections. By acting as bridges, APIs (Application Programming Interfaces) enable real-time data sharing and reception between your WMS and other systems. By serving as a manager and translator, middleware makes sure that various systems "speak the same language" and that there are no interruptions or delays in the constant dependable data flow. As your company expands and diversifies, this networking layer is necessary for scalability and flexibility.

Ultimately, a well-integrated WMS strategically benefits your whole supply chain. Just as essential as what happens inside your facility is how your warehouse operations support everything from manufacturing and ordering to distribution and customer experience. When your WMS is a part of a coordinated ecosystem, it facilitates better options, faster delivery, and greater service levels.

Strategic Benefits of Implementing WMS

Using a warehouse management system (WMS) can help you do more than just upgrade your technology; it can also provide you strategic advantages that impact your whole business. A well-managed WMS not only streamlines processes but also transforms them into a competitive advantage.

One of the most obvious advantages is increased accuracy. By automating important processes like order picking, shipment verification, and inventory tracking, a WMS significantly lowers human error. There will be fewer stock variations and returns as a result, and your data will be far more trustworthy.

Improved inventory turnover is strongly associated with increased accuracy. Businesses minimize carrying costs while optimizing the value of each square foot in the warehouse by maintaining optimal stock levels and getting rid of extras or dead stock. It's a more intelligent and lean method of inventory management.

Moreover, there is a notable increase in customer satisfaction. A better purchasing experience is made possible by real-time tracking, quicker order fulfillment, and fewer errors. Trust and loyalty come easily to clients who regularly receive the correct goods on schedule.

Labor becomes more efficient on an internal level. In addition to guiding employees via the best selecting pathways and reducing idle time, a WMS assists in job allocation based on real-time priority. Getting more done with the same crew without experiencing burnout is the outcome of workforce optimization.

Scalability also becomes crucial as your firm expands. Expanding SKUs, new locations, and changing workflows are all seamlessly accommodated by a strong WMS. With the assurance that your operations can meet demand, it allows you to grow.

A WMS, to put it simply, is a strategic asset that promotes long-term profitability, operational excellence, and customer satisfaction.

Choosing the Right WMS for Your Business

Your whole business, from everyday operations to long-term expansion, is shaped by your choice of Warehouse Management System (WMS). With so many alternatives available, it's important to match your decision to the particular requirements and long-term goals of your company.

Analyzing your essential needs should come first. Think about how big your business is, how many orders you process, how many SKUs you oversee, and if you require multi-site assistance. Equally crucial are integration requirements: will your WMS have to communicate with your e-commerce, ERP, CRM, or TMS platforms? Your operation will function more smoothly the more interconnected your system is.

Selecting between an on-premises and cloud-based WMS is a major choice point. Cloud-based solutions are perfect for expanding enterprises or those with many locations because they provide flexibility, remote access, fewer upfront expenses, and automated upgrades. Yet, on-premise systems offer more customization and control but come with a larger upfront cost and the need for specialized IT staff.

Compliance and security should never be examined after the fact. Verify that the WMS you select complies with industry standards, supports data governance guidelines, and has strong user access control, data encryption, and frequent backup capabilities.

This brief comparison of three well-liked WMS alternatives will help you make an informed choice:

| WMS Solution | Deployment | Best For | Key Features |

| NetSuite WMS | Cloud | Mid to large businesses | Integrated with ERP, real-time data |

| Fishbowl Warehouse | On-Premise | Small to mid-sized companies | Inventory control, QuickBooks integration |

| Manhattan Associates | Cloud/On-Prem | Enterprise-level operations | Advanced analytics, omnichannel support |

| Zoho Inventory | Cloud | E-commerce and SMBs | Multichannel selling, barcode scanning |

| SAP Extended WM | On-Premise | Large enterprises | Deep ERP integration, global scale |

The WMS that best suits your operations, connects with your ecosystem, protects your data, and expands with your company is ultimately the "right" one. Spend some time analyzing your present issues and long-term objectives; your warehouse will appreciate it.

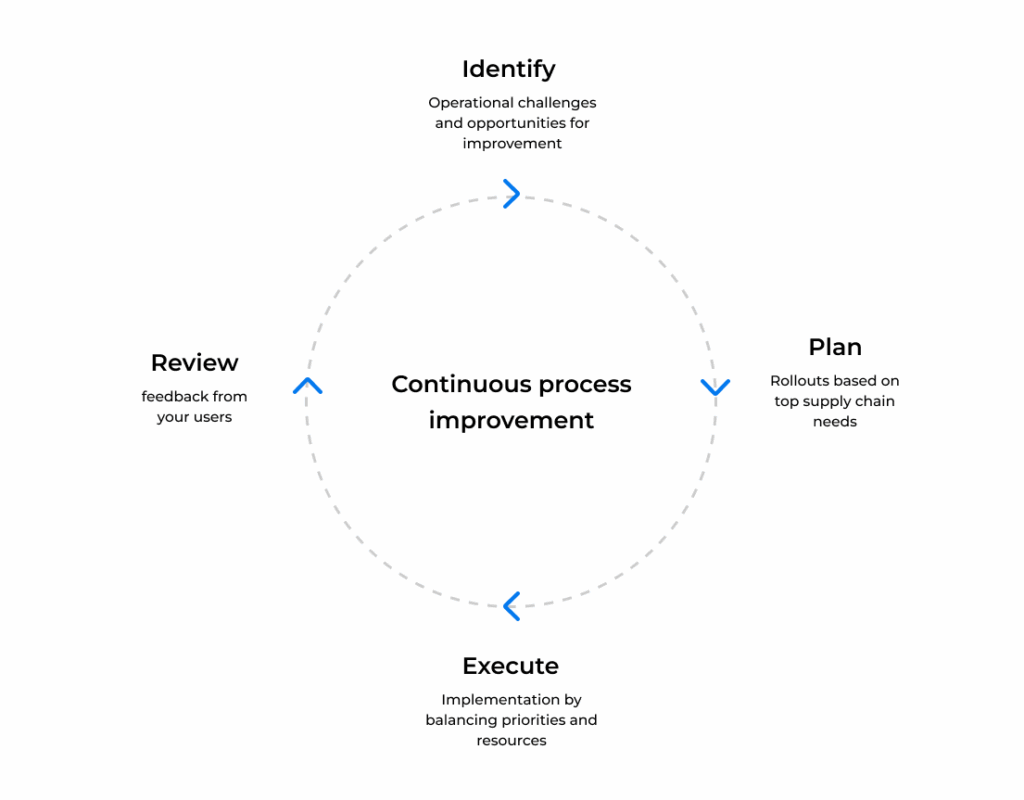

Implementation Strategy and Best Practices

A warehouse management system (WMS) implementation is a strategic change rather than just a software installation. A well-defined plan and tried-and-true best practices that transform complexity into clarity and disturbance into success are necessary to get it right.

Planning and a readiness evaluation are the first steps. Prior to implementing any technology, assess your current procedures, establish your objectives, and coordinate important parties. This stage guarantees that your WMS solution is customized to your operational reality rather than trying to suit it, and that you're built on a strong basis.

Data migration and system configuration follow. Any WMS depends heavily on clean, accurate data. Transferring old data, standardizing formats, and establishing user roles, workflows, and automation rules for replicating your actual operations are all part of this step. The system begins to take shape at this point.

Closely followed by change management and staff training. No matter how strong your system is, its effectiveness depends on its users. Your team may confidently accept the shift with the help of leadership support, clear communication, and practical training. People become less resistant when they feel empowered and equipped.

The time has finally come to go live and make sure post-implementation assistance is available. It's important to launch your WMS in phases, whether you want to roll it out gradually or with a huge bang. Furthermore, committed support guarantees that any issues are promptly fixed when it goes live and that your system keeps developing to meet your needs.

Implementing a WMS correctly changes the way your entire company functions, not just increasing warehouse efficiency. A wise plan now positions you for long-term success later.

Metrics and KPIs for Warehouse Performance

Optimizing warehouse performance requires monitoring the appropriate parameters. These Key Performance Indicators, or KPIs, provide real-time information about operational effectiveness and point out areas that require improvement:

- Order Cycle Time

Calculates the time it takes to ship an order; shorter cycles result in quicker fulfillment and more satisfied customers. - Inventory Accuracy

Compares system-recorded inventory to actual physical counts—high accuracy ensures reliable stock levels and fewer order errors. - Dock-to-Stock Time

Measures the amount of time it takes for received items to be available in stock; shorter turnaround times translate into quicker processing and better stock control. - Picking Accuracy Rate

Calculates the frequency of correctly picked orders; greater accuracy lowers returns and increases customer satisfaction. - Labor Utilization Metrics

Determines how well workers spend their time on useful tasks, which is essential for cutting expenses and increasing productivity.

Frequent monitoring of these KPIs promotes continuous improvement throughout your warehouse and aids in maintaining operational excellence.

Common Challenges in Warehouse Management

Challenges develop in even the most well-planned warehouse operations; some are related to people and procedures, while others have deep roots in technology. The first step in overcoming these obstacles is acknowledging them:

- Legacy Systems and Resistance to Change

Modern solutions can be slowed down by outdated software and ingrained behaviors. Strong leadership, transparent communication, and training that is user-focused are necessary to overcome this. - Integration Complexities

Technically speaking, integrating a WMS with ERP, CRM, TMS, and other systems might be challenging. Ensuring smooth data flow is important since inadequate integration results in data silos and workflow disruptions. - Cost and Time Overruns

WMS projects might take longer than expected and go over budget if they are not properly planned. With the help of a clear scope, phased deployment, and ongoing mistakes, things remain on track. - Cybersecurity Risks in Cloud-Based WMS

Although cloud systems are flexible, they also need strong security measures. To protect sensitive data, it is essential to use encryption, access limits, and frequent audits.

By being aware of these difficulties, you can take proactive steps to reduce risks and create a warehouse operation that is not only effective but also flexible.

Future Trends in Warehouse Management

Smarter, faster, and more sustainable warehouse management is the way of the future. The following trends are influencing the next generation of warehouse operations as technology advances:

- Autonomous Warehouses

Robotics, artificial intelligence, and little human involvement are enabling fully automated facilities. These warehouses offer reduced labor expenses, lightning-fast fulfillment, and round-the-clock operation. - Predictive Analytics for Stock Optimization

Predictive technologies, which go beyond historical data, foresee demand, seasonal changes, and purchasing patterns, assisting warehouses in improving inventory planning and lowering overstocking or stock outs. - Green and Sustainable Warehousing

Eco-friendly techniques are becoming more popular, such as solar energy, recyclable packaging, energy-efficient lighting, and intelligent HVAC systems. Warehouses are starting to play a major role in business sustainability strategies. - Blockchain in Warehouse Transparency

Products may be tracked securely and impenetrably throughout the supply chain thanks to blockchain technology. It boosts traceability, makes compliance and audits easier, and builds trust with partners.

These are not just futuristic trends; forward-thinking businesses are already using them. You may stay competitive in a rapidly evolving logistics world by accepting them.

Final Thoughts: Is Your Business Ready for a Modern WMS?

Using a modern WMS can revolutionize your entire warehouse business; it's not just a technical advancement. It's time to think about deploying a WMS if you're having trouble scaling, dealing with inventory problems, or facing inefficiencies. However, keep in mind that selecting the best technology, organizing a seamless deployment, and providing your staff with training are important for success.

Is your company prepared? The entire potential of your warehouse may be unlocked with a WMS if you want to increase accuracy, boost labor efficiency, cut expenses, and stay ahead of the competition. Welcome to the storage of the future.