Why Top Manufacturers Are Betting on Production Management Software in 2025

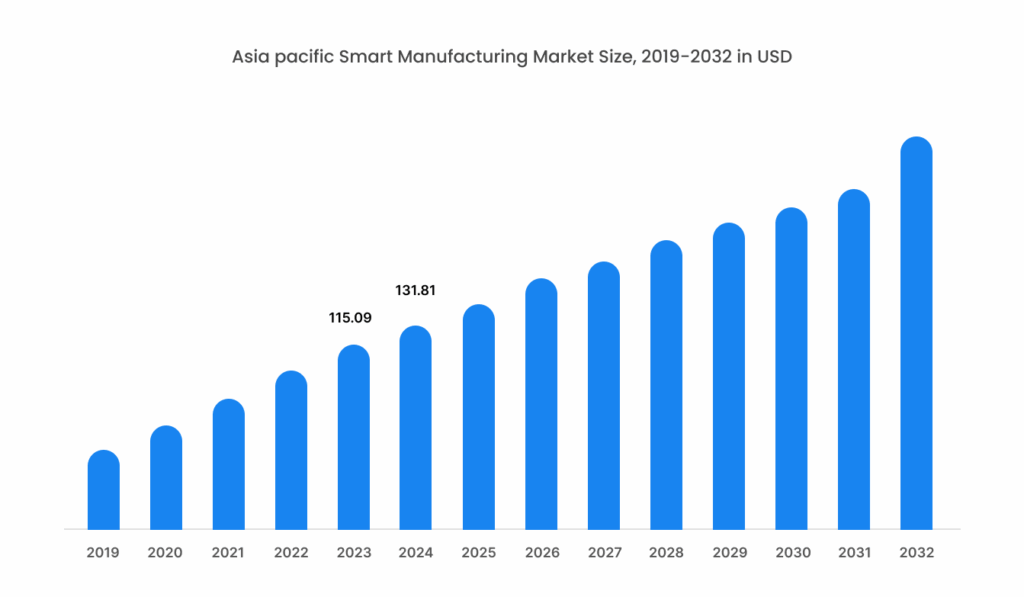

Manufacturing is evolving faster than ever, and data, automation, and smart technologies are driving all of it. Fortune Business Insights expects that the worldwide smart manufacturing market would increase from $394.35 billion in 2025 to more than $998.99 billion by 2032, at a CAGR of 14.2%. Production Management Software (PMS) is at the heart of this transformation—a tool that's no longer simply "nice to have," but important to all businesses looking to remain competitive in 2025 and beyond.

So, what is Production Management Software?

Simply said, it's a digital brain for your manufacturing. It integrates all moving parts (machines, materials, people, schedules, and data) into a single streamlined system. Instead of managing spreadsheets, emails, and manual checklists, manufacturers now have a real-time, bird's-eye view of their whole manufacturing process. It enables processes to be managed better, quicker, and with fewer errors, from raw materials to finished product.

Why It’s a Game-Changer in Modern Manufacturing

In an era where every second matters, production management software enables manufacturers to achieve more with less. It automates planning and scheduling, eliminates downtime, monitors KPIs in real time, and enables data-driven decisions on the fly. With AI and system learning now integrated into many platforms, certain structures may even anticipate issues before they occur, such as detecting a system about to break or a delay in the supply chain.

This kind of adaptability is becoming increasingly important in projects. According to a Deloitte survey from 2024, 72% of factory executives believe that digital transformation, including tools such as PMS, would be the most important driver of productivity during the next five years.

Who Needs It: SMEs vs Large-Scale Manufacturers

The beauty of today's software is its scalability. Production control software provides a way for small and medium-sized companies to automate processes without paying expensive up-front expenses. Many cloud-based platforms now include flexible pricing, plug-and-play functionality, and mobile access, making high-volume production manageable even for underdeveloped countries.

PMS serves as a command center for large manufacturers. It facilitates complex processes across several locations, languages, and vendors. It ensures uniformity, traceability, and overall performance monitoring across the whole global supply chain.

Core Concepts of Production Management

To fully understand the importance of production management software, one needs to understand the basic concepts of production management—what it is, what kinds of production systems it supports, and how software is changing the game.

What is Production Management?

Production management is the strategic planning, coordination, and control of production operations that ensures things are produced efficiently, on schedule, and within budget. It includes everything from managing labor and supplies to improving operations and ensuring product quality.

Traditionally, this required an immense amount of manual oversight—spreadsheets, clipboards, and gut feelings. Digital technologies are changing the whole approach to production management, making it more data-driven, transparent, and flexible than ever.

Types of Production: Mass, Batch, Job & Continuous

Manufacturing processes are not all the same—and production management must adapt to the particular problems of each kind.

- Mass Production: Consider this high-volume, standardized manufacturing—similar to automobile assembly or packaged food. Speed and consistency are important. PMS helps here by simplifying scheduling, reducing downtime, and maintaining quality across hundreds (or millions) of units.

- Batch Production: Products are manufactured in groups or batches (for example, baked products and medications). Flexibility is important since each batch may change somewhat. PMS facilitates this through recipe management, changeover tracking, and batch traceability.

- Job Production: This requires bespoke production, which is frequently one-of-a-kind or limited in quantity. Detailed planning and exact tracking are essential, and PMS enables visibility at every stage of the work, from bid to delivery.

- Continuous Production: Non-stop manufacturing operations, which are common in sectors such as oil refining and chemicals, need strict control and a zero tolerance for error. PMS provides 24 hour monitoring, predictive maintenance, and real-time quality inspections.

Each of these production kinds has different obstacles, but they all benefit from the same thing: a smart, centralized system that helps in complexity management, waste elimination, and increased efficiency.

The Role of Software in Modern Production Management

Production Management Software is more than simply a digital update; it represents a fundamental transformation in the way factories work. By replacing old, segmented systems with a single source of truth, PMS allows manufacturers to:

- Optimize planning and scheduling using AI-driven tools

- Visual dashboards provide real-time monitoring of performance.

- Automate repetitive activities and reduce human error.

- Ensure traceability and compliance in regulated sectors.

- Increase collaboration across departments and even continents.

In short, PMS empowers manufacturers like never before. It transforms raw data into usable insights, allowing teams to respond more quickly and intelligently, and laying the groundwork for future advancements such as predictive analytics and digital twins.

Read the Complete Guide to Software Solutions That Boost Productivity and Encourage Development to Unlock Your Manufacturing Potential!

Production Management Software vs Production Planning Software

It's easy to get caught up in the language of industrial technology. Production Management Software (PMS) and Production Planning Software (PPS) may sound similar, but they have separate (but complimentary) purposes. Understanding the important differences and overlaps may be useful manufacturers in selecting the best tools for their needs—or determining when both are required.

Key Differences and Overlaps

| Feature | Production Planning Software | Production Management Software |

| Primary Focus | Planning before production begins | Managing the process during and after production |

| Key Functions | Forecasting, material planning, production scheduling | Monitoring, execution, quality control, workflow optimization |

| Time Frame | Typically forward-looking | Real-time and historical tracking |

| Users | Planners, supply chain managers | Plant managers, floor supervisors, operations teams |

| Integration | Often used with ERP or MRP systems | Often integrates with MES, ERP, and IoT systems |

Production Planning Software is all about establishing the rules: identifying what needs to be manufactured, when, how, and with what resources. It is about estimating demand, scheduling jobs, and ensuring resources are available before production begins.

Once manufacturing begins, however, manufacturing Management Software takes over. It promotes on execution—ensuring that work is completed efficiently, measuring progress, and continually improving along the way.

There is undoubtedly overlap—especially as platforms become more integrated—but PPS tends to be more strategic and forward-thinking, whereas PMS more tactical and executional.

When You Need One vs. Both

- When to Choose Planning Software Only:

If your primary difficulty involves organizing future production, controlling resources, or optimizing schedules—and your execution processes are currently operating smoothly—you may be able to get by with only PPS. This is frequently true for small manufacturers with regular workflows. - When to Choose Management Software Only:

If your schedules are solid but execution is chaotic (delays, downtime, complicated performance statistics), PMS can provide clarity and control on the shop floor. It is critical for manufacturers trying to grow or implement real-time visibility. - When You Need Both:

The majority of expanding or mid-to-large manufacturers will profit from combining their systems. Planning and execution cannot be separated, and when they are, you get a full-circle view: predict, plan, create, adapt, repeat—with actual data flowing throughout the process.

This synergy—between planning and management—is what enables smart factories to remain flexible, optimize continually, and meet greater performance targets year after year.

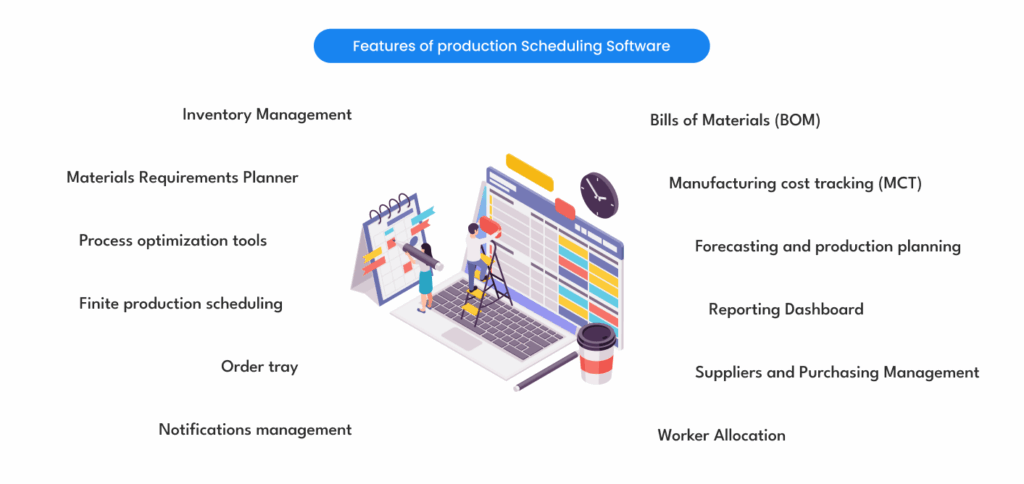

Key Features to Look for in Production Management Software

Software for production management is not all made equal. The greatest solutions, given the large number of equipment available in 2025, are those that integrate scalability, intelligence, and usability—all while directly addressing the day-to-day challenges present in modern production. Here are the essential features to look for when choosing a platform, whether you're upgrading to a better one or choosing your first one:

Real-Time Inventory & Supply Chain Visibility - You can prevent shortages, overstock, and bottlenecks by keeping an eye on dealer timeframes, supplies, and stock in real time.

Demand Forecasting & MRP - Estimate the demand accurately and auto-calculate fabric preferences to reduce waste and maintain production schedules.

Workforce & Resource Scheduling - Workloads may be distributed across teams and machines, shifts can be optimized, and responsibilities can be assigned without the need for guidance.

Workflow Automation - Preserve production transfer without delays or misunderstandings by automating duties and expediting approvals.

In-Line Quality Control - Track quality in real time with traceability and quick defect notifications to stop problems before they get out of hand.

IoT-Enabled Machine Monitoring - Establish a direct connection with equipment to keep an eye on maintenance, performance, and downtime—avoid malfunctions before they arise.

Live Dashboards & KPI Tracking - Personalized dashboards offer real-time data (such as yield, downtime, and OEE) to help make better decisions.

Role-Based Access & Data Security - Manage who can view what. Make sure that strong permissions, logs, and cloud security are followed.

AI & Predictive Analytics - Utilize AI to identify hazards, streamline processes, and anticipate malfunctions before they affect output.

Benefits of Production Management Software

Purchasing production management software not only updates your operations but also changes how your whole company runs. Here's how a well implemented PMS benefits businesses in the real world, from increased productivity to satisfied clients.

Increased Efficiency & Productivity

Teams are released from manual coordination and firefighting by automated scheduling, real-time performance tracking, and quicker decision-making.

Impact: Without additional workers or equipment, manufacturers estimate output increases of 20–30% (McKinsey, 2024).

Reduced Costs & Waste

Overproduction, excess inventory, and downtime are the main causes of expenses. Demand-based planning, predictive maintenance, and stricter quality control are how PMS reduces them.

Bonus: Helps reduce energy use and waste from raw materials, both of which are important for achieving sustainability goals.

Easier Compliance & Audit Readiness

Industries under regulation require precise and spotless records. Batch tracking, quality checks, and traceability documentation are all automated by PMS, which keeps you constantly audit-ready.

No more: Hastily obtaining paper logs or running the danger of breaking them.

Stronger Cross-Team Collaboration

When manufacturing, spending, QA, and logistics are all connected by a single system, silos vanish. Task automation and shared dashboards keep everyone in together, from the C-suite to the shop floor.

Higher Customer Satisfaction

Deadlines that are missed destroy client trust. By proactive schedule management, early risk alerts, and resource optimization, PMS helps you deliver on time.

Result: Client satisfaction, shorter lead times, and higher delivery rates.

Selecting the Right Production Management Software

Finding a system that matches your processes, grows with your business, and helps your team achieve outcomes is more important than just checking boxes when selecting production management software. Here's how to confidently make that choice.

Build vs Buy: What’s Right for Your Business?

Whether to purchase an off-the-shelf platform or develop a custom solution is one of the first issues that firms ask. Each has advantages and disadvantages.

- Build (Custom Software):

Custom software is developed from the ground up to precisely match your workflow. Manufacturers with highly specialized operations will find it suitable.

✅ Pros: Fully tailored, competitive edge

⚠️ Cons: High cost, longer rollout, dependency on developers - Buy (Commercial Software):

These days, commercial platforms have been selected by most manufacturers. They are scalable, easier to manage, and faster to implement.

✅ Pros: Faster ROI, tested and proven, scalable

⚠️ Cons: Less customization (though this is changing fast)

Implementation Roadmap

Selecting the best production management software is just half the battle; the real change starts with its effective implementation. A hasty or badly executed launch may cause opposition, conflict, or even disruptions to operations. A well-organized, people-centered implementation roadmap is therefore crucial.

Here's how to properly introduce your PMS, from preparation to complete acceptance:

Step-by-Step Deployment Process

- Assessment & Goal Alignment

Establishing a clear definition of success should come first. Are you trying to cut down on downtime? Enhance timely delivery? Systems integration? To ensure alignment on goals, get feedback from leadership, IT, and production. - Vendor Selection & Solution Mapping

Once your objectives have been established, closely collaborate with your vendor to sketch out how the software will be set up to fit your team structure, production processes, and compliance requirements. - Pilot Deployment (Start Small)

Start with a pilot—one facility, one department, or one line. Before implementing it throughout the whole organization, this enables you to evaluate functionality, get feedback, and make adjustments. Consider it to be your "learning lab." - Full Rollout & Training

Scale in stages. Emphasize comprehensive training for users (not only IT, but also operators and supervisors). Make it interactive, role-based, and accompanied by video tutorials or cheat sheets. - Performance Monitoring & Optimization

After going online, monitor important KPIs like throughput, cycle time, and OEE to spot opportunities and gaps. When it comes to continuous development, PMS really excels.

System Integration with ERP, CRM, MES, SCM

PMS works best when it’s not isolated. Seamless integration with your broader tech stack unlocks full visibility and control:

- ERP: Sync financials, procurement, and inventory

- CRM: Align orders and production with customer needs

- MES: Enable shop floor tracking and real-time execution

- SCM: Coordinate materials, suppliers, and logistics in real-time

To speed up and simplify this procedure, modern PMS solutions include pre-built connections and API-based connectivity.

Customization for Unique Business Workflows

Each manufacturer is unique. A appropriate PMS should enable you to:

- Workflows and approval routes can be customized.

- Create dashboards for specialized roles, such as quality vs production.

- Establish guidelines for tasks, escalations, and notifications.

- Reports should be formatted to meet internal or regulatory requirements.

Look for a platform that provides this flexibility without which demands extensive technical insight to execute modifications.

Change Management and Stakeholder Buy-In

The success of even the greatest software depends on the involvement of humans. Adoption requires transparency, support, and trust.

- Empower Champions: Determine which early adopters may set an example.

- Communicate Clearly: Explain how the PMS will streamline everyday duties and lower conflict.

- Support Actively: Provide support on-site, training seminars, and help desks.

- Celebrate Wins: Share early improvements to create momentum and raise spirits.

Future Trends in Production Management Software

Faster, smarter, and more networked manufacturing is bringing in a new era. As factories transition from isolated to interconnected, and from reactive to predictive, Production Management Software (PMS) is at the forefront of this change. The following major trends will shape PMS in the future:

Smart Factories & Industry 4.0

What’s happening:

Cloud computing, IoT, and AI are turning plants into intelligent ecosystems. Real-time communication is now possible between machines, sensors, and systems.

What it means for PMS:

Your PMS turns into the digital control center, keeping an eye on equipment, planning malfunctions, and automatically modifying procedures to minimize downtime and increase productivity.

Where it's going:

Your PMS turns into the digital control center, keeping an eye on equipment, planning malfunctions, and automatically modifying procedures to minimize downtime and increase productivity.

AI & Machine Learning Take the Lead

What’s happening:

When it comes to identifying trends, forecasting maintenance, and streamlining production plans, artificial intelligence is filling the gaps left by traditional analytics.

What it means for PMS:

Not only does your program identify problems, it also fixes them. Auto-adjustments, real-time recommendations, and intelligent scheduling will soon be standard.

Where it's going:

As PMS develops into self-learning systems, processes will continually improve without the need for human input.

Blockchain for Transparent Supply Chains

What’s happening:

Supply networks throughout the world require traceability. Presenting blockchain, a safe, unbreakable method of tracking items from production to delivery.

What it means for PMS:

Every transaction will be recorded on an electronic record by future-ready PMS, increasing accountability, lowering fraud, and guaranteeing authenticity all the way through the chain.

Where it's going:

End-to-end, auditable visibility that simplifies compliance and fosters consumer trust.

Change Your Manufacturing Processes Right Now! Collaborate with Our Skilled Staff to Create Tailored Manufacturing Software Solutions That Simplify Your Procedures and Quicken Development.

Digital Twins & Simulation Modeling

What’s happening:

Physical change testing is expensive. You may simulate and optimize without any kind of delay by using digital twins, which are virtual representations of machines or processes.

What it means for PMS:

Manufacturers may test results, adjust processes, and remove challenges before implementing changes in the real world.

Where it's going:

Full-factory simulations will help make better judgments about everything from maintenance planning to layout modifications.

Cloud, On-Prem, and the Rise of Hybrid Models

What’s happening:

Cloud-based PMS is becoming more popular due to its scalability and flexibility. However, on-premises configurations are still used for security in sensitive businesses.

What it means for PMS:

There are new hybrid solutions that combine on-premises governance and compliance with cloud analytics and mobility.

Where it's going:

infrastructure that can be tailored to your requirements, guaranteeing privacy of information, agility, and reliability.

Conclusion

PMS, or production control software, is increasingly necessary to maintain excellence. Digitising your manufacturing processes not only ensures excellent control, increases productivity, and reduces costs, but it also positions your company for success in an increasingly automated and information-driven environment.

By using PMS to preserve your production techniques, your company may increase customer pride, streamline processes, and make more informed decisions. The ability of PMS to offer management, flexibility, and visibility may also benefit a small producer looking to grow or a large firm streamlining practices. Through system automation, real-time record monitoring, and smooth connection with other business systems, PMS builds the foundation for an intelligent manufacturing facility that can quickly adjust to changes in the market and operational requirements.

By reducing human error and providing real-time insights to assist you identify production issues, PMS will help you future-proof your operations. Its advantages are self-evident. But remember, digitizing your output is an ongoing process. Keeping up with technological advancements and streamlining your system will guarantee that your PMS offers the most value.

Choosing a PMS solution is essential if you want to satisfy your current requirements and grow with you in the future. Follow these procedures to guarantee scalability at the end:

- Select Scalable Software: Pay attention to cloud-based solutions, which may expand with your company. Easy improvements, smooth technological connections, and adaptability to new product strains or growing manufacturing volumes are all provided.

- Invest in Customization: Your PMS must be updated to reflect changes in your business organization. Collaborate with your software provider to adjust reporting features, connections, and strategies as your needs grow. Your machine's level of modification will enhance its overall performance in your particular manufacturing environment.

- Embrace Innovation: Blockchain, the Internet of Things, and artificial intelligence are some of the technologies that will drive manufacturing in the future. Make sure your PMS can work with these advancements to offer additional automation, predictive maintenance, and supply chain transparency.

- Continuous Training and Support: Make sure your staff members are regularly informed on the latest features and industry best practices. Regular training will enable them to maximize system performance, and continuous assistance will reduce interruptions.

- Monitor and Adapt: Keep an eye on and adjust: The industrial industry is always changing. To keep up with shifting market needs, legislative changes, and technological breakthroughs, compare your PMS on a regular basis to important performance standards.

Your PMS rollout will go more smoothly if you place a higher priority on adaptability, creativity, and a continuous development culture. Likewise, you will create the foundation for ongoing success and expandable expansion.